Packaging development:

All under one roof

Latest since the commitment made at the World Economic Forum in January 2018, brand owners and retailers are looking for more sustainable packaging solutions. With our GuiltfreePlastics®, a functional bioplastic, you can produce flexible packaging that is up to 90% from a renewable resource, 100% recyclable post-industrial as well as post-consumer, and offers 100% biodegradability as end-of-life option.

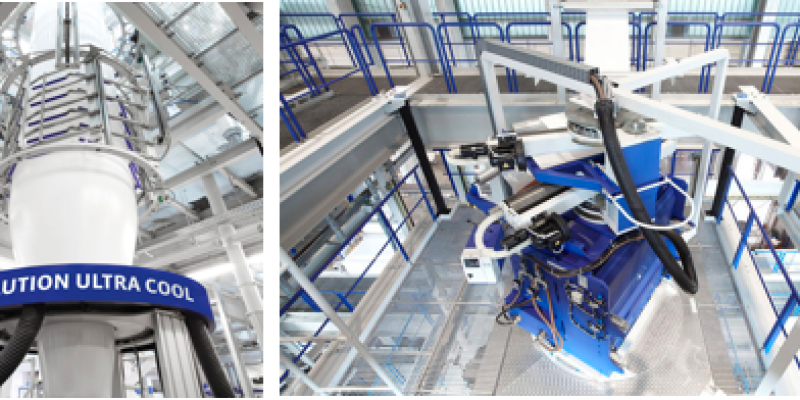

Application centre

To speed-up the packaging development, we invested in an industrial-scale bioplastics application centre, located in Figueira da Foz (Portugal). With a focus on flexible packaging, we installed state-of-the-art machines from some of the world’s leading equipment manufacturers. Within a secure environment we can produce specific compounds, blow multi-layer films, perform mono-directional orientation, print 6-colour high-quality images, and test sealability on conversion lines. make this facility available to select brand owners / retailers, who share our vision for sustainable packaging.

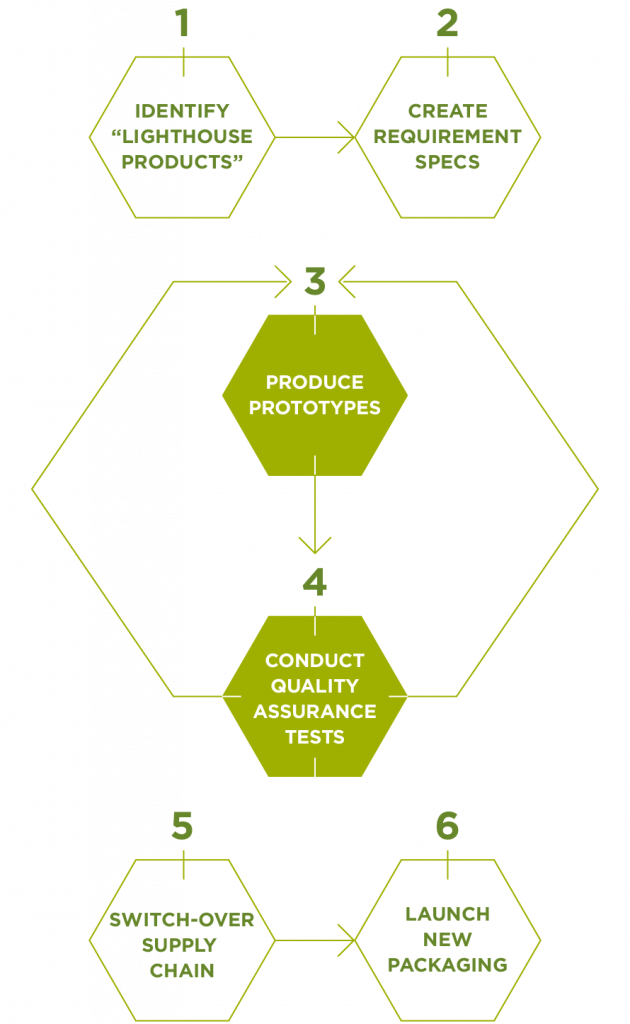

Offer for brand owners

We invite brand owners to identify, together with us, “lighthouse products”, for which a flexible packaging with biodegradation as an end-of-life option makes sense. Based on a detailed specification document, we shortlist product formulations from our extensive database. We then grant brand owners access to our proprietary bioplastics application centre. Within a secure environment, we can produce the pellets, blow multi-layer films, test printing quality, as well as the films sealability. In combination of in-house and outsourced labs, we conduct quality assurance tests of the newly developed films. Once, the film meets the brand owner’s requirements, we can switch-over their existing supply chain to GuiltfreePlastics® – hence facilitation a smooth launch of the sustainable packaging solution.